|

|

Introduction

Ch1 - Welcome to Microhydro

Ch2 - Getting the service you want

Ch3 - Determining your power potential

Ch4 - About battery-charging systems

| • |

4.1 What kind

of service can you expect from a battery charging

system? |

| • |

4.2 Tell me

about batteries in microhydro |

| • |

4.3

Turbines: high head, low head |

| • |

4.4 Charging

batteries with alternators |

| • |

4.5 Getting

AC from batteries with an inverter |

| • |

4.6 Battery

charge controlling by diversion controlling |

| • |

4.7 Transmitting

power up to a mile to charge batteries |

Ch5- About AC systems

Ch6- Plumbing

Ch7- Case studies

Ch8 - Regulations and incentives

|

|

|

|

|

|

|

The following in an excerpt from Chapter 4.3 Turbines: high head,

low head.

Back to course description

There are several different kinds of turbines that are appropriate

for battery charging systems. The classic microhydro unit for

a battery-based system is an impulse turbine, a design that relies

on relatively high head and low flow.

An impulse turbine gets its energy from the impact of a spray of

water. A nozzle, also called a jet, at the end of the pipeline

converts the water under pressure into a fast moving jet of water,

which sprays little cups on the turbine wheel, also called a runner.

The kinetic energy from the water spins the runner.

This kind of turbine has the

advantage of being able to operate at a wide variety of heads and

flows, and thus a single model of wheel can be used in many sites.

Common impulse turbines are the Pelton, the Turgo and the Crossflow,

the latter being a popular home-built design.

Turbines are classified according to the head that they require.

Of the three impulse turbines mentioned, the Crossflow

turbine is used for the largest flow, lowest head situations in

the range of 4 to 20 feet. The Pelton is used in situations

where the head is as high as 600 feet, and is especially designed

for low flow. The Turgo has similar head requirements, but

can handle more flow than the Pelton.

Low head for battery charging systems means heads under 10 or 12

feet. Turbines that work in this range are reaction type turbines,

for example the LH-1000 from Energy Systems and Design.

The Aquair offers a completely different solution. The Aquair

has a propeller that sits directly in the creek and spins with the

current of the water.

Some of these turbines are described below. This section

will also explore building your own. After all, water turbines

have been around for thousands of years.

4.3.1 High head turbines

Pelton

The original and classic microhydro turbine design is the Pelton.

Invented in the 19th century by directing water jets used in hydraulic

mining onto overshot water wheels, it provided a way to get the

high rotating speeds necessary for electrical generating.

It is used especially for low flow battery-charging systems, where

the head is over 30 feet or so. It requires at least ten feet

of head.

An example of a Pelton wheel is the four-inch

Pelton designed by Harris Hydroelectric. It will generate

with as little as 2 US gpm, and it will accommodate up to four half-inch

jets to handle more flow.

This Harris Hydroelectrc unit (left) has four jets and

a permanent magnet alternator mounted on the top. The runner

(right) handles high pressure water.

The maximum power potential of the Harris Hydroelectric turbine

is 1 kilowatt. If your site has a lot more potential, you

would probably benefit from choosing a larger wheel, or choosing

a Turgo design which can handle more flow.

The Harris Hydroelectric Pelton comes with a choice of alternators:

a Harris Hydroelectric permanent magnet alternator, a Motocraft

80 amp alternator or a 30 amp Delco alternator, which will affect

the power output. These alternators will be covered in more

detail in Charging batteries with alternators.

Turgo

The Turgo runner is a refinement of the Pelton, where the jets

direct water at the runner at an angle. The Turgo is used

especially for situations with high water flows; the design allows

for larger jets. Because Turgos can use more water, significant

power can be generated with less head. This results in shorter

penstocks, all things being equal.

In addition the Turgo is rugged and can be used as a small and

inexpensive AC turbine for the right kind of site, making it a commonly

used turbine.

An example of a Turgo turbine is the Stream

Engine from Energy Systems & Design, a Canadian company

who have been producing microhydro turbines since 1980. Their turbines

have a 4-inch bronze runner.

This Stream runs two Stream Engines protected in a plexiglass

covering(left). A view from the underside of the unit (right)

shows off the 4-inch bronze Turgo runner.

The Stream Engine can produce over 700 kW/hr per month. It can

be equipped with up to four

universal nozzles that are adjustable with threaded inserts

from 1/8 to a maximum of one inch. In comparison, the Harris

Hydroelectric Pelton can only accommodate 1/2-inch jets.

Like the Harris Hydroelectric Pelton, a variety of alternators

can be fit the turbine, such as an automotive alternator or a brushless

permanent magnet alternator.

The

Waterbaby

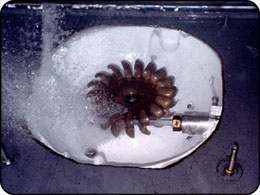

Perhaps

the smallest impulse turbine is the Waterbaby by Energy Systems

and Designs. There is no other way to describe it -- it’s

simply cute. The runner is only 2 inches across, with a design

somewhere in between a Pelton and a Turgo. It will efficiently

produce outputs down to 18 kWhrs/month and costs about CAN$1750.

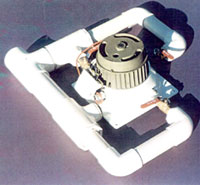

The Waterbaby with alternator (left) and the two-inch runner

(right).

top

|